Lm7 Wiring Harness Layout

Mar 02, 2011 In part one we show how to begin disassembling a 4.8L/5.3L/6.0L Truck harness in order to modify it to work on an LS1 intake and be fully compatible with an older wiring. This is the best case scenario, you’ll only need to buy the appropriate wiring harness with the right connectors on each end. If your late model car, truck, or SUV does not have a trailer package from the factory, you may go with a T-connector made specifically for your make and model. Trailer Wiring Diagram. To connect the electric.

Welcome to Speartech!Home of the original LS swap harness developed here over 20 years ago!We have standalone swap harnesses and complete control systems for all 99+ LS engines/transmissions.We have standalone swap harnesses and complete control systems for new Gen 5 LT engines/transmissions, with LT5 harness development underway now!Looking for a complete, turn key powertrain package? You've come to the right place - we have packages available for LS3, LT1, and LT4!We are the source for 6L80/6L90 and 8L90 swap accessories including tap shift products, reverse light CAN relay, neutral safety switch, and more!Give us a call to get your LS/LT swap project out on the road and start enjoying today's power and reliability in the old classics you love! Speartech - The Original & Still The Best!(765) 378-4908Current harness lead time: 7-8 weeks.

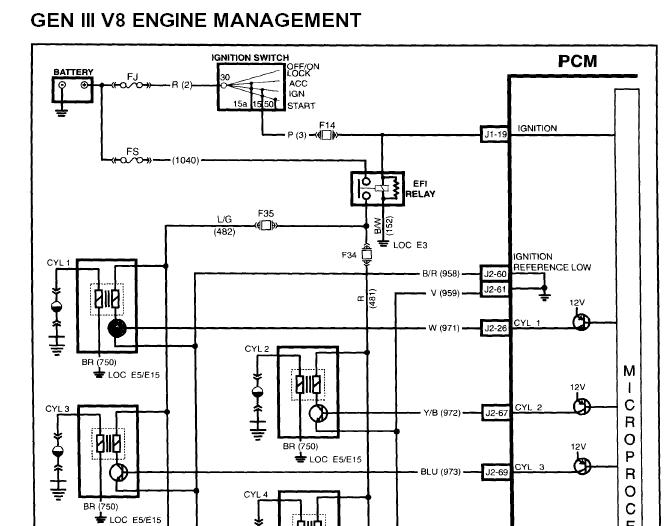

Wiring Harness InformationWWW.LT1SWAP.COMVisit mypage for a lot of New Pictures & Harness Guideschannel for How Tovideos - E-Mail:Here is some information for LT1, LS1, Vortec 4.8, 5.3, 6.0 wiring harnesses. Thereshould be enough here to get you going in the right direction. Some of these Ihave pictures of completed harnesses I have modified for easy installation.I have a lot of pictures so please be patient and let them load. If youfind this information useful, or have suggestion on something to add, I will try toget it done. My goal isto help the hobbyist to be able to complete a harness transformation by themself. I would only hope you send the PCM to me when it comes time for it.I do not charge for ANY information.Thanks!-Brendan. Sample schematic similar to what you may see in the following pages. This may help you to learn how to read the schematics1992 to 1997Includes: Camaro/Firebird, Corvette, Caprice/Impala, Roadmaster1996 to 19991999 to 2007 TONS OF INFO HERE, Please Readall the pages linked.2007 to 2009- New Harness Modification INFO added 11/6/2012!2010 to 98 to 2002 - New PCM Pinout info specific to 98, 99-02F-body.

Wiring Harness For Cars

3/30/2013- Wiring harness info specific to the 2004 GTO LS1- Adam will rework most LS1, Vortec Truck, and F-Body LT1 Harnesses- Purchase new harnesses for swaps, Vortec 4.3, 5.7, 7.4, LS, LT, Truck lots of applicationsTypical 'External' Connections.thisapplies to most any GM wiring harness.12v+ Battery Connection - The computer requires a batteryconstant connection. This is so the PCM can remember learned information aboutthe engine over time.

This includes idle control, fuel trims, andtransmission adapts. Its very important that the battery hot wires(usually ORANGE) are hot all the time.Key 12v+ Connection. The PCM also gets 12V+ from a KEYHOT source. This is what 'powers up' the PCM. Its important that this keyhot power, along with power to injectors, coils, and so on, STAY HOT whencranking over the engine. Some accessory positions on key switches ARE NOT HOTwhen cranking.

This also includes older vehicles that had POINTS ignition. Eventhe COIL wire on some of those went dead when cranking. This is because whencranking the coil was boosted to 12v+ through the R terminal on the startersolenoid. After cranking, power was restored to the coil through aresistor, lowering voltage to 6 volts.Fuel Pump Relay Control - The computer on GM fuelinjection systems is designed to control a fuel pump relay. The computerdoes this by supply a 12v+ (POSITIVE) signal to the relay.

The signal isonly present for two seconds at key on. Fuel pump operation resumes whencranking over. The PCM ONLY commands it back on when the PCM reads thatthe engine is turning over. So, if there is a condition where there is a badcrank sensor, fuel pump will come on, turn off, and will not turn on whencranking.Brake Switch Signal - For automatics with lock upconverter, the PCM needs signal when brake pedal is pressed. However, thesignal needed is opposite how you're brake lights work. The PCM wants 12v+constant on this wire when brake IS NOT pressed, and OPEN Circuit whenthe brake IS pressed.

If you vehicle was equipped with a lockup trans tobegin with, you probably already have the proper normally closed switch mountedby your brake light switch. If you do not, you can use a relay to performthe same thing. On most relays, there are 5 terminals, 2 of them turn the relayON when provided ground/power. There are then a normally open leg and anormally closed leg on the relay and a supply. By feeding 12v+ on thesupply leg, and hooking the Brake Switch Signal wire to the normally closed leg,you will now have the correct signal for the PCM. When the brake ispressed, 12v+ flows to brake lights, tap into this wire, and run it to the relayto turn the relay on.

This will cause the normally closed leg tobecome open, thus turning OFF the 12v+ signal to the PCM. When you releasethe brake pedal, the relay will turn OFF, and then feed 12v+ to the PCM.VSS Signal - This wire is a 4000 pulse per mile signalfrom the PCM used by some aftermarket speedometers.

This can also be usefor the electric cruise control boxes used on early 90s GM cars & trucks.PCM can be programmed to match tire size and axle ratio for you're swap, so thissignal is calibrated. Chrysler/Jeep vehicles typically need a 8000pulse/mile signal to run the speedometer.TACH Signal - On 1993 LT1 withdistributors, this comes from the negative side of the coil. Later LT1 andon LS1, Vortec 4.8/5.3/6.0 this comes from the PCM, which generates this signal for aaftermarket tachometer. The stock LS tach signal is 4 cylinder typesignal. This can be programmed as 4, 6, or 8 cylinder signal. Some 2003+LS PCM's tach signal is not strong enough, and needs boosted.Fan Controls 1,2 - GM PCM's typically will controlelectric fans, usually 2. The PCM will supply the (negative) or GROUND signal toturn on fan relays.

YOU CAN NOT DIRECTLY CONNECT PCM FAN CONTROL WIRE TO FANS.YOU MUST USE A RELAY.How to wire up a fan relay.using a (negative) or GROUNDcontrol from PCMWire going to terminal 30 & 87 should be 10-12 gauge to handlethe current draw of the cooling fan. Terminals 85 & 86 can use 16-22 gaugejust fine. Relay coil draws less then 1 amp. Make sure the ground for the cooling fan is a good one, alsoensure there is a good ground from the battery ( - ) side to the frame.Use this schematic to wire up a DUAL SPEED fan such as the Ford Taurus fan.This uses a 5 terminal relay for the on on the right in this schematic.When the HIGH speed kicks in, it removes power from the first relay. Mount and blade warband proficiencies.

Thisprevents power from being applied to both wires of the fan at the same time.If you want your fan or fans to turn on with a/c compressor, you can use thefollowing wiring to do that. The label 'TO FAN RELAY CONTROL (-) cansplice into the wire from the PCM to the FAN relay. This way the PCM can stillcontrol the fan when A/C is off, or when A/C is commanded on, the fan comes onright away.Here are some pictures of a typical automotive relay that can befound at most parts stores.Contact InfoBrendan Patten7227 Private Road 1830West Plains MO 65775.